As consumer demands evolve, retailers place higher expectations on suppliers. Today’s consumers know they don’t have to wait for an item they want. They can find it on another store shelf or online. To ensure the item is there for the Walmart customers when they want it, Walmart launched the On-Time In-Full (OTIF) initiative in 2017.

OTIF has seen many changes since its launch, but its purpose has remained the same: Improve the supply chain to keep items in stock.

There are many details related to OTIF. It is incumbent on the supplier to know these and comply with them. This content is an overview of OTIF, not a comprehensive presentation.

What Is On Time In Full (OTIF)?

It is Walmart’s expectations for On-Time and In-Full delivery.

Walmart’s On-Time In-Full initiative is a measure of how a supplier’s freight arrives at a Walmart store, fulfillment center, or distribution center. As its name states, Walmart is asking two questions of each supplier delivery:

- Did the shipment arrive on-time? Walmart assigns a specific drop-off window for each delivery. The delivery is considered On-Timeime if it arrives within the window. Early and late deliveries may both be subject to monetary penalties charged back to the supplier.

- Did the shipment arrive in-full? The expectation is that what the supplier delivers to Walmart matches exactly what is listed on the purchase order (PO). Any discrepancy, whether in quantity or product, may result in monetary penalties charged back to the supplier.

Why Does OTIF Matter?

The reason behind OTIF is simple: To keep the shelves full and make sure the item is in-stock whenever the customer wants it.

Sales, profit, in-stock, positive customer experience, and almost everything in retail depend on a smooth supply chain. OTIF puts the supply chain under the microscope and shows where improvement is needed. Suppliers with excellent supply chains have better OTIF scores and more sales. Flaws in your supply chain and non-compliance with OTIF goals results in poor OTIF scores and monetary penalties.

“By consistently meeting – or exceeding – Walmart OTIF standards, suppliers can achieve a competitive advantage on store shelves by ensuring consistent product flow through DC and store networks,” advises Kevin Williamson, the CEO of RJW. “This leads to better in-stocks, on-shelf availability, sales throughput, market share, and consumer loyalty. Timely, accurate deliveries are critical for supplier success. The stronger your OTIF scores are, the more success you’ll see at the shelf.”

Keep in mind that the decision to penalize suppliers for not complying with OTIF expectations was never for Walmart to make money. It was to stress the importance of suppliers’ improving their supply chain to keep Walmart shelves and warehouses stocked with merchandise.

What Is a Good OTIF Score?

Hitting 100% on both the on-time and in-full is, of course, the ideal. But Walmart recognizes that perfection is challenging, so these are the goals as of March 2024:

Prepaid suppliers: 90% OT and 95% IF

Collect suppliers: 98% OT and 95% IF

A common question from Walmart suppliers is, “If we’re not delivering at goal yet, how low can our on-time and in-full metrics be to still be in an acceptable range?”

This can only be answered by your Walmart merchant team, but generally you are expected to be at goal.

Sometimes (but very rarely) outside factors impacting the supply chain can provide lenience in Walmart’s view on acceptable OTIF performance. Walmart recognizes there can be uncontrollable disruptions in the supply chain. Disastrous weather can stop shipments completely. The 2020 pandemic changed consumer demand on select items and brought unforeseen shortages. During such events, Walmart factored the events into OTIF performance or waived penalties altogether.

How Is OTIF Calculated?

OTIF is calculated on two metrics that are in a PO:

- If deliveries arrive on the assigned delivery date window

- If the freight is fully delivered

If a supplier fails to meet the OTIF guidelines on a delivery, they are fined 3% cost of goods on all cases that did not meet the goal.

ON-TIME

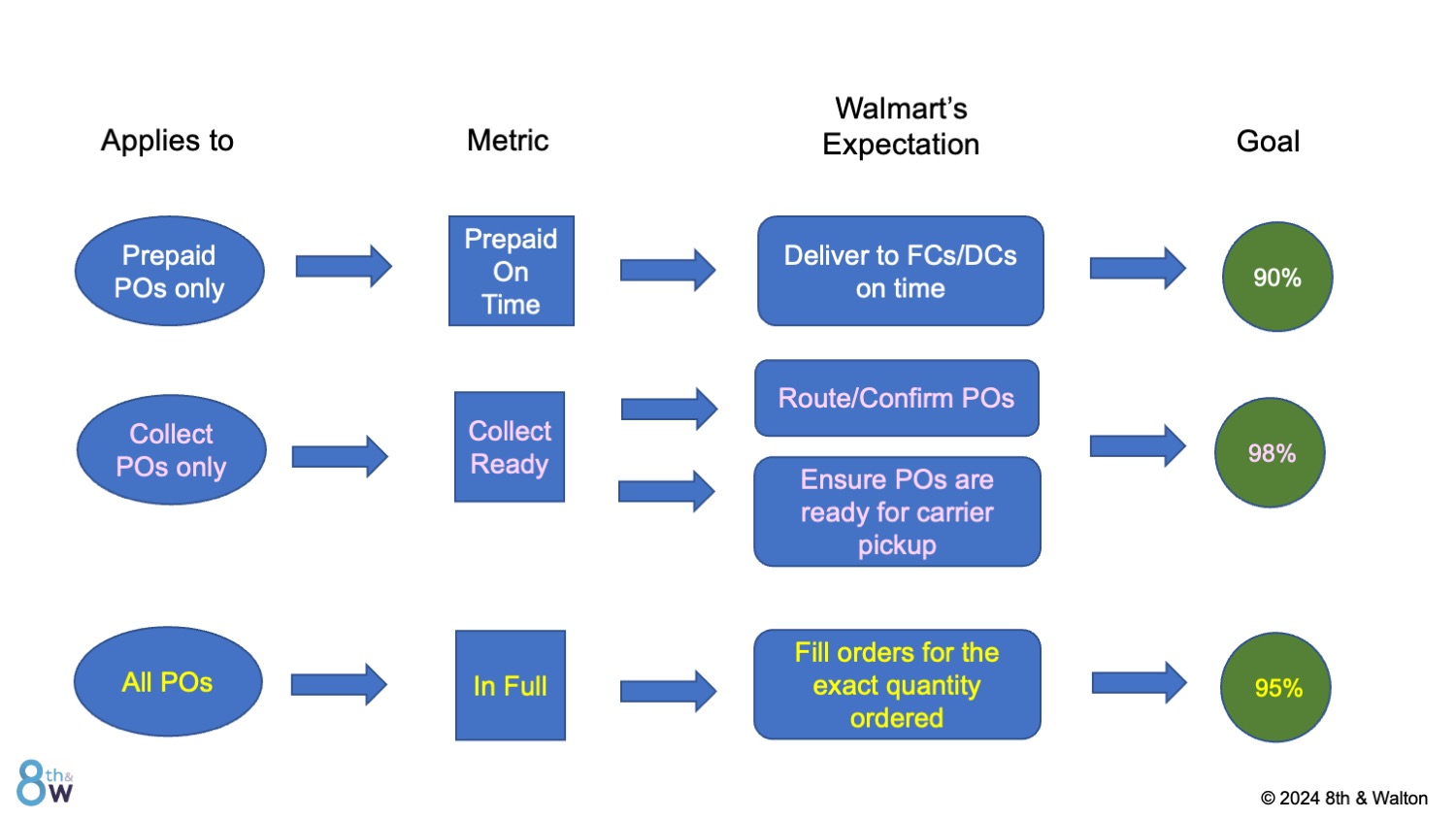

The On-Time goals and expectations differ for prepaid and collect suppliers.

Prepaid suppliers have a goal of 90% On-Time and must deliver to the warehouse, distribution center, or fulfillment center on time.

Collect suppliers have a goal of 98% On-Time and must ensure shipments are ready for carrier pick-up on time. They are held accountable if they route late or don’t have goods ready to go at the dock when the Walmart truck arrives. (Collect POs should always be routed within 24 hours of receipt of PO or by 4 PM Central Time, whichever is first.)

IN-FULL

All suppliers — whether prepaid or collect — have the same In-Full goal of 95% and are expected to fill orders for the exact quantity ordered.

Here’s are some examples that may help you understand —

An On-Time error:

- Your PO states that the shipment will arrive on January 10.

- The full shipment arrives but not on January 10. It arrives a week late.

- You will be fined 3% cost of goods of the shipment since it was not On-Time.

An In-Full error:

- Your PO states that you will ship 100 cases that will arrive on a certain date.

- Cases arrive when expected, but the order is incomplete. You are 15 cases short.

- You will be fined 3% cost of goods for the 15 missing cases because the order was not In-Full.

Both an On-Time and an In-Full error in the same PO:

- Your PO states that you will ship 100 cases that will arrive on January 10.

- Your shipment is one week late, and you ship only 85 cases.

- You actually ship only 85 cases. You are 15 cases short.

- You will be fined 3% cost of goods for the 85 cases that arrived late (not On Time).

- You will be fined 3% cost of goods for the 15 cases you did not ship (not In-Full).

Supplier expectations for OTIF have changed each year since its debut. Initially performance percentages had some variations — different goals for different store categories, for example. Today, on-time and in-full expectations are the same for all prepaid suppliers, and on-time and in-full expectations are the same for all collect suppliers, too. Any supplier performance falling short of the goals will be penalized.

Other significant considerations:

- If you are not yet a Walmart supplier, it is important to understand OTIF expectations before applying. For more information on the supplier application process, check out our blog How to Sell to Walmart: Get Your Product in Walmart in 4 Steps.

- OTIF goals also apply to Walmart.com suppliers. If you are delivering to the fulfillment center, your goals are exactly the same as those stated above.

- OTIF is cumulative by month. That means you have a full month in which to meet the goal. If you have a shipment that came in under goal, do your best to follow up with a better performing shipment so your average for the month is at goal.

- OTIF charges are calculated and displayed monthly but billed quarterly.

- If the total OTIF penalty for a month is under $1,000, it will be waived.

- 8th & Walton offers an in-detail class specifically on OTIF.

How to Improve OTIF Performance

If your OTIF performance is not meeting Walmart’s expectations, the result will be fewer sales and higher penalties. Before the monthly penalties become too great (and the risk of losing product placement on the modular becomes real), take the necessary steps to improve your OTIF performance:

1. Understand Your Walmart OTIF Scorecard

Walmart allows suppliers to track their OTIF performance in Retail Link® with the OTIF Scorecard. It’s a great tool to monitor your performance, see potential issues, and avoid being penalized for non-compliance.

If you have questions about the Walmart OTIF Scorecard, the 8th & Walton team will go over it with you during a free consultation.

2. Fix PO Issues First

In-Full accuracy links back to what is listed on the PO. Make it a regular practice to verify that the product being shipped to Walmart and the quantity match what is on the PO.

If you are out of an item requested on the PO, do not substitute. This will result in a penalty. Item data on the PO must be accurate.

Walmart may change or even cancel a PO. Work with your team to be notified automatically of any PO changes or cancellations.

3. Talk With Your Walmart Merchant

Are you producing enough products today to meet your Walmart merchant’s expectations in six months? What new promotions, marketing initiatives, or store growth will impact orders?

Knowing your merchant’s plans allows you to forecast accurately and plan better shipments. Develop a strategy together to improve your OTIF score.

4. Consider Using a Third-Party Consolidator

Small and mid-sized suppliers can get crushed trying to keep up with OTIF penalties each month. Turning supply chain tasks over to a third-party logistics and consolidating firm can save your business time and payroll dollars.

Aside from warehousing and transportation, most third-party firms handle your appointment schedules and reduce charges by consolidating your partial truckloads with other suppliers. This creates one full truckload arriving at the Walmart distribution center.

“When choosing a 3PL partner for retail consolidation, prioritize experience and expertise,” adds RJW’s CEO Kevin Williamson. “Look for a provider with a proven track record, especially with major retailers like Walmart. The right 3PL will leverage advanced analytics technology and flexible solutions to reduce your total transportation costs, optimize inventory replenishment, and keep your products consistently in-stock, ultimately boosting sales.”

Third-party consolidators currently approved by Walmart already understand Walmart’s expectations for OTIF, documentation, notices, stock transfers, shipment status updates, and more. Partnering with them can quickly improve supply chain performance.

5. Stay Up-to-Date on OTIF Changes

Walmart will notify suppliers in advance of changes in OTIF expectations. It is important to monitor communications from the company in Retail Link® as well as staying in touch with your Walmart merchant team.

To learn more about OTIF classes or to work with a Walmart expert, 8th & Walton has dedicated teams for all levels of suppliers. Contact us today to set up a free 15-minute consultation about your OTIF needs.

Conclusion

Adherence to the Walmart OTIF supply chain expectations will improve your in-stock and result in better sales. If your OTIF performance begins to slip, penalties can grow and you risk having your product removed from Walmart’s modular.

Make OTIF a priority in your organization by using the tools and scorecards in Retail Link® and working with your Walmart merchant team.

For up-to-date information on improving your supply chain and OTIF score, consider taking a class from 8th & Walton. Content to help you brush up on supply chain excellence is updated as Walmart updates its guidelines.