Consolidation has become a hot topic in the supplier community. There are many reasons why the practice of putting loads from multiple companies on a single truck is good business, and these range from financial to environmental. What many people don’t realize, however, is that the benefits of consolidation don’t stop with the supplier.

How the Consolidation Cycle Benefits Everyone

While consolidation is marketed toward suppliers, make no mistake: Everyone from the supplier to retailer to the end consumer benefits. Here are a few key ways that consolidation serves all three points in the consolidation cycle (supplier, retailer, consumer):

Supplier

- Reduces costs and improves margins

- Can improve product placement

- Opens opportunity for cross-promotion

- Improves Supplier Scorecards and OSA

Retailer

- Helps keep products on the shelf

- Decreases dock congestion

- Eliminates need for order minimums

- Reduces inventory cost

Consumer

- More products on the shelf, consistently

- Lower prices

- More brands to choose from

- Fewer trucks on the road so less traffic congestion and pollution

Third Party Practical Solutions

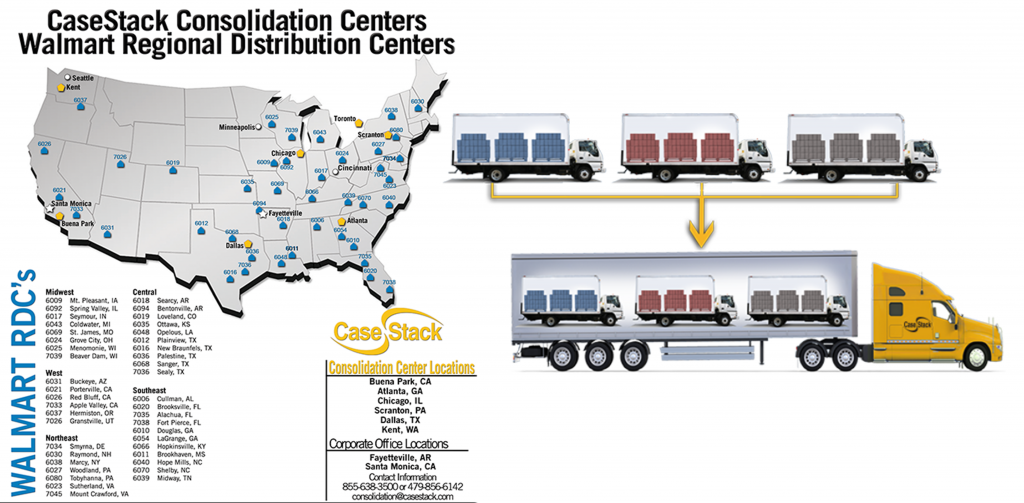

While the benefits of consolidation are definitely holistic, the decision to hire a consolidator ultimately belongs to the supplier. A third-party consolidator like CaseStack can help a supplier identify areas of possible waste so that the supplier can correct the problem and reduce costs and environmental impact.

While the benefits of consolidation are definitely holistic, the decision to hire a consolidator ultimately belongs to the supplier. A third-party consolidator like CaseStack can help a supplier identify areas of possible waste so that the supplier can correct the problem and reduce costs and environmental impact.

An example of this type of issue was brought up in a recent episode of Focus on Suppliers. CaseStack’s Colby Beland noted that packaging that is puffed up with a lot of air can be problematic:

“[Packaging with lots of air space] — that’s valuable space on the shelf to the retailer. That’s valuable real estate, but more importantly that’s real estate being taken up in the truck so you can’t put as much product on the truck. The greater the number of cases that are shipped on the inbound, the more product that you can put on the truck, and the more your costs come down. So this will also reduce over time the number of trucks on the road. So it’s packaging whether it be weight or space, and reducing the packaging requirements is a sustainable initiative.”

Sometimes suppliers become so identified with the way they’ve been doing things that they can’t spot problems and opportunities like these. As a result, they may miss simple fixes that could make a huge difference for everyone in the consolidation cycle.

Final Word

Suppliers who are considering consolidation but wondering if it is really worth it should try thinking beyond their own company. Consider how shifting to consolidated shipments can serve your business clients as well as the end customer. CaseStack stands ready to answer questions from suppliers who want to know about next steps.